CNNC successfully completed the disassembly and repair of the first domestic helium valve

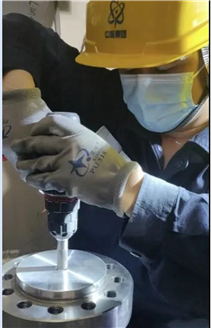

At 11 o'clock on July 17, the helium valve carried out a tightness test. The pressure was maintained for 5 minutes, and there was no bubble leakage, which was far higher than the technical standard-the leakage rate of 5 bubbles in 5 minutes of pressure retention, marking the high standard and high efficiency of China National Nuclear Corporation. To complete the maintenance work.

A few days ago, a helium shut-off valve of Huaneng Shidaowan Nuclear Power Plant needs to be disassembled and inspected before cold test. Because the valve is a nuclear first-class equipment, it is an isolation valve of the pressure boundary of the primary circuit, and it is located in the two cold rooms of Huaneng Shidaowan Nuclear Power Plant. The key points and difficulties of equipment maintenance for a thermal key node, and the maintenance results will have a vital impact on the valve maintenance of high-temperature gas-cooled reactors in the future. As the main force in the maintenance of nuclear islands in my country's nuclear power plants, CNNC has undertaken the maintenance task of this valve.

On July 7, the company’s chairman and party secretary Zeng Hao and his entourage visited Huaneng Shidaowan Nuclear Power Plant and communicated with Zhang Tao, deputy chief engineer of Huaneng Group, Hu Shouyin, general manager of Huaneng Shidaowan Company, etc., expressing that China National Nuclear To ensure the smooth progress of Huaneng Shidao Bay nuclear power key nodes.

After the meeting, Zeng Hao immediately asked the Nuclear Power Business Department to arrange relevant forces to fully support the work of Haiyang Branch. The Nuclear Power Division responded quickly and organized and transferred the company's valve technical experts overnight to the Shidaowan Nuclear Power Plant to assist in the maintenance of the helium shut-off valve. On July 8, the valve technical experts of the company arrived at Huaneng Shidaowan Nuclear Power Plant with tools and materials. After studying the drawings of the valve and surveying the site with Huaneng’s owner’s technical experts, they finally determined a feasible maintenance plan and improved the existing Special tools for valve maintenance. During the construction, the grinding technology of CNNC's maintenance valve was unanimously praised by the technical specialists of the owner of Huaneng. On July 17, the task was completed with high standards.

The high-standard completion of the valve maintenance work has enabled China Nuclear Power to win the full trust and high praise of the Huaneng owners, and laid a good foundation for the maintenance process and sealing verification standards of helium valves in the future.

Huaneng Shidaowan Nuclear Power Plant adopts the world's fourth-generation nuclear power technology-high-temperature gas-cooled reactor. It is the first high-temperature gas-cooled reactor under construction in China. It is a milestone in the development of China's nuclear power technology.

It is strictly for industrial valve testing and inspection and ,one type 600LB double block and bleed valve in Cowinns was tested and inspected successfully for zero leakage in one South American.